Description

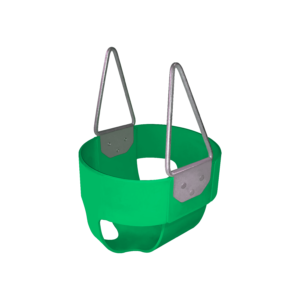

A Belt Swing Seat Replacement for Schools and Parks

The commercial belt swing seat is uniquely crafted with numerous safety features to protect the children and students. The seat for swings is built using a new, innovative design consisting of a single steel insert encased in EPDM rubber and rust-resistant welded triangular hardware.

The higher safety standards for school and park swing seats include:

- Prevents cuts if the rubber is ever torn off

- Resistant to cracks and deterioration

- Avoids triangle hardware from being pulled off

Belt Swing Seat Dimensions

- 24” x 6” x 5/16” or 30 ¼” hanger to hanger

Benefits of an EPDM Seat for Swings

The belt swing seat is encased in ethylene-propylene-diene-monomer (EPDM) synthetic rubber offering commercial-grade benefits, including:

- Prevents the swing seat from crazing, cracking, and oxidizing

- Inhibits moisture from getting into the swing seat which prevents deterioration

- Does not transfer rubber marks on children’s clothes

- Holds up in extreme temperatures, both very hot and very cold

- 70 duro rubber hardness

Benefits of a One-Piece Steel Insert

The belt swing seat is created using a single steel insert to provide schools and parks a durable, commercial playground swing seat.

- Greatly increases the strength of the seat

- 1075 rounded edge steel insert

- Painted with a non-rusting adhesive

- Coated with rubber that is from ¼” to ⅜” thick

Commercial Welded Triangle Details

The school and park swing seat features triangular hardware individually welded together so they cannot be pulled apart or pulled off the seat.

- Constructed of ⅜” diameter, cold rolled steel with the ends welded together

- Plate is 1/16” thick h.r. stamped galvanized steel

- Rivets used to rivet the plate through the EPDM rubber and steel insert are made of ¼” diameter steel

- Three rivets on each side of the seat

The belt swing seat should last 2 years in harsh conditions and up to 5 years in optimal conditions. Tensile strength is 5300 lbs.